When medical companies search for:

titanium CNC machining service

medical device CNC machining supplier

precision titanium surgical components

custom titanium CNC parts manufacturer

CNC machining supplier China

They are not just looking for a factory.

They are looking for:

• dimensional stability

• controlled tolerance

• surface integrity

• burr-free edges

• consistent batch production

Titanium is widely used in:

Surgical instruments

Implantable components

Orthopedic connectors

Medical housings

Endoscopy structural parts

Especially Titanium Grade 5 (Ti-6Al-4V).

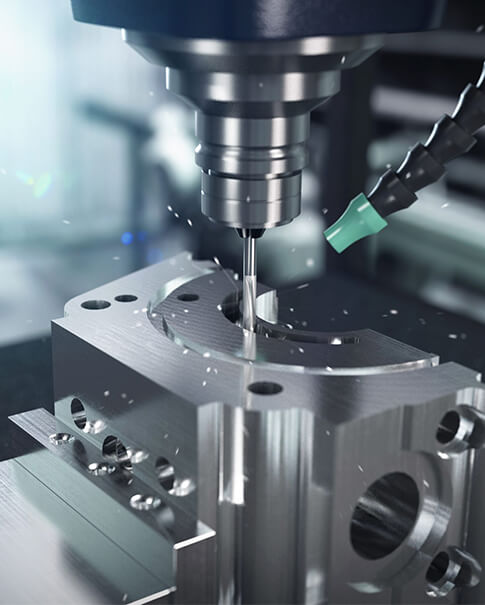

But machining titanium is different from machining aluminum or stainless steel.

Titanium has:

Low thermal conductivity

High strength

Tendency to work harden

Tool wear sensitivity

High cutting resistance

Many companies bidding on:

CNC titanium machining China

titanium prototype machining

precision medical CNC components

often underestimate tool life and heat management.

Poor machining strategy leads to:

✖ tool burning

✖ dimensional drift

✖ surface micro cracks

✖ high scrap rate

A European medical startup found us after searching:

titanium CNC machining prototype with tight tolerance

They required:

120 pcs titanium housing

Tolerance ±0.015mm

Smooth surface for surgical environment

Small batch production

Initial sample from previous supplier had:

• visible tool marks

• edge burr

• internal dimension deviation

Before production, we confirmed:

✔ drawing tolerance critical zones

✔ surface roughness requirement

✔ material certificate requirement

Then we modified machining strategy:

1️⃣ Reduced cutting speed

2️⃣ Used high-pressure coolant

3️⃣ Applied multi-step finishing pass

4️⃣ Added manual deburring inspection under magnifier

Result:

Scrap rate reduced from 9% → below 2%

Surface roughness Ra < 0.8

All parts passed inspection

Delivery within agreed schedule

Medical machining is not about speed.

It is about control.

As a CNC machining supplier in Shenzhen, we provide:

3 axis / 4 axis / 5 axis CNC machining

Tight tolerance ±0.01mm

CNC milling service

CNC turning parts supplier

Rapid CNC machining China

Materials:

Titanium Grade 2

Titanium Grade 5 (Ti6Al4V)

Stainless Steel 304 / 316L

Aluminum 6061 / 7075

Medical brass components

Finishing:

Precision polishing

Sandblasting

Anodizing

Passivation

Electropolishing

We can provide:

Material report

Dimension inspection report

First article inspection

Photo confirmation before shipment

For buyers searching:

custom titanium CNC parts

medical device CNC machining service

low volume titanium machining

titanium prototype manufacturer

We support both prototype and small batch production.

Titanium machining is expensive.

But cost can be optimized by:

✔ reviewing unnecessary tight tolerance

✔ optimizing tool path

✔ reducing deep cavity design

✔ adjusting wall thickness if possible

✔ selecting proper material grade

Many RFQs we receive for:

get CNC machining quote

upload drawing for quotation

titanium CNC machining supplier

often include over-engineered tolerance that increases cost 15–25%.

We help customers reduce that — before cutting metal.

Medical buyers care about:

✔ engineering communication

✔ stable batch quality

✔ controlled lead time

✔ risk reduction process

Our cooperation process includes:

Before Production:

Final drawing confirmation

Packing & labeling confirmation

Surface & tolerance confirmation

After Production:

QC inspection

First sample confirmation

Material certificate

Before Shipment:

Invoice & HS confirmation

Product photos

Logistics tracking sharing

That’s how we control risk.

If you are looking for:

titanium CNC machining service China

precision medical titanium parts manufacturer

small batch titanium CNC supplier

rapid CNC machining prototype

Send us:

• STEP / IGS / PDF drawing

• Material grade

• Surface finish

• Quantity

We will respond within 4 hours.