Published on : February 2026

Category : Food-Grade Blade Machining, Precision CNC Cutting Tools, Food Processing Components, Sanitary Blade Manufacturing

Tags : Food-Grade Blade, CNC Machined Food Blade, Sanitary Food Processing Blade, Stainless Steel Food Blade, Custom Food Cutting Blade, Food Safety Blade Manufacturing

Food processing is an industry where safety is non-negotiable—every component that comes into contact with food must meet strict hygiene, non-toxicity, and corrosion-resistant standards. Food-grade blades, as the core component of food processing equipment (meat cutters, vegetable slicers, bakery mixers, fruit juicers), directly affect food safety, processing efficiency, and product quality. Unlike ordinary industrial blades, food-grade blades require not only exceptional sharpness and durability but also compliance with global food safety standards (FDA, EU 10/2011, GB 4806) to ensure no metal contamination, corrosion, or toxin release during use.

With 15+ years of precision CNC machining experience and deep expertise in food-grade component manufacturing, GT Prototype specializes in food-grade blade production and customization. We focus on solving the core pain points of food processing enterprises: blade rusting, dulling quickly, food residue adhesion, and non-compliance with food safety standards. Our food-grade blades are machined using food-safe materials (304/316L stainless steel, food-grade titanium alloy), integrated with precision CNC machining, sanitary polishing, and food-safe post-processing—delivering products that balance safety, sharpness, and durability. If you’re searching for a reliable food-grade blade manufacturer that meets global food safety standards and offers custom solutions for different food processing scenarios, this article details our core production capabilities, real customer cases, and why we’re trusted by food processing enterprises worldwide.

Core Capabilities for Food-Grade Blade Manufacturing: Safety & Precision as the Core

Food-grade blade manufacturing is a rigorous process that requires strict control over material selection, machining precision, surface treatment, and quality inspection—every step is related to food safety. At GT Prototype, we’ve built a dedicated food-grade component production line (compliant with food safety hygiene standards), combining advanced CNC equipment, food-specific machining processes, and strict quality management systems to ensure every blade meets global food safety requirements:

✅ Food-Safe Material Selection: The Foundation of Food Safety

Material selection is the first line of defense for food-grade blades. We exclusively use food-safe materials that meet FDA, EU 10/2011, and GB 4806 standards: 304 stainless steel (for general food processing blades, such as vegetable slicer blades), 316L stainless steel (for high-humidity, acidic food processing, such as fruit juicer blades and meat cutter blades—superior corrosion resistance), and food-grade Ti-6Al-4V titanium alloy (for high-end, high-wear scenarios, such as bakery dough cutting blades—lightweight, non-toxic, and wear-resistant). All materials are sourced from certified suppliers and come with material safety certificates (MSDS), and we conduct strict incoming material inspections to ensure no heavy metals, harmful impurities, or non-food-grade additives.

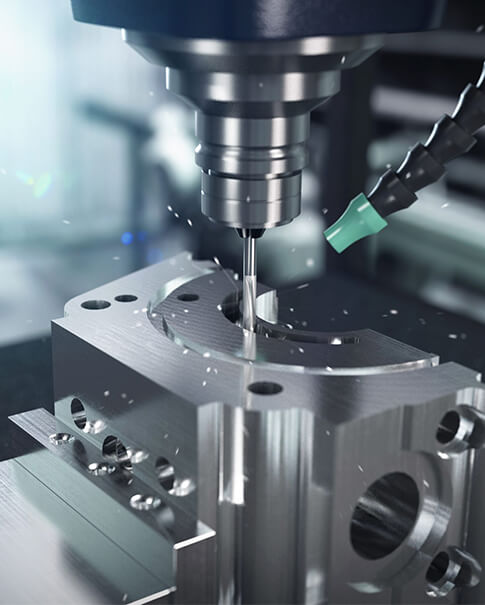

✅ Precision CNC Machining: Ensuring Sharpness & Dimensional Stability

Food-grade blades require high machining precision to ensure sharpness, uniform cutting, and compatibility with food processing equipment. We use high-precision 3 axis, 4 axis CNC machining centers (Haas VF-2, DMG MORI DMC 635 V) with high-speed spindles and precision tooling—capable of machining blades with a cutting edge sharpness of ≤0.01mm, tolerance of ±0.002mm, and surface flatness of ≤0.003mm. Our senior CNC engineers optimize the tool path and cutting parameters for different food-grade materials: for 304/316L stainless steel blades, we use carbide tools with TiN coatings to avoid burrs and ensure a smooth cutting edge; for titanium alloy blades, we adopt low-speed, high-feed machining to prevent surface defects. We also conduct on-machine probing during machining to monitor dimensional accuracy in real time—avoiding thermal deformation and ensuring every blade has consistent sharpness and size.

✅ Food-Specific Surface Treatment: Sanitary & Anti-Adhesion

Surface treatment of food-grade blades is critical to preventing food residue adhesion, corrosion, and bacterial growth. Our food-specific surface treatment processes include: sanitary polishing (Ra ≤0.2μm surface finish—smooth surface, no dead corners, easy to clean and disinfect), passivation treatment (enhancing corrosion resistance of stainless steel blades by 70%, preventing rusting in high-humidity food processing environments), and anti-adhesion coating (food-safe Teflon coating for sticky food processing blades, such as dough cutting blades—reducing food residue adhesion and improving cutting efficiency). All surface treatment processes are food-safe, non-toxic, and non-volatile, and we conduct strict surface inspection to ensure no coating peeling, uneven polishing, or surface defects.

✅ Strict Quality Inspection: Compliance with Global Food Safety Standards

Quality inspection for food-grade blades is more rigorous than ordinary industrial blades—we implement a full-process quality control system from incoming materials to final delivery. Our inspection items include: material composition testing (ensuring compliance with food safety standards), dimensional accuracy inspection (CMM, Zeiss Contura G2), sharpness testing (cutting force test, cutting uniformity test), surface finish inspection (surface roughness tester), corrosion resistance testing (salt spray test, acidic food simulation test), and food safety testing (heavy metal detection, non-toxicity testing). Every blade must pass all inspection items before delivery, and we provide a detailed quality inspection report and food safety compliance certificate—ensuring you can use our blades with confidence in food processing.

Real Customer Cases: Food-Grade Blade Solutions for Different Food Processing Scenarios

We have delivered thousands of sets of food-grade blades to food processing enterprises in 50+ countries, covering meat processing, vegetable and fruit processing, bakery, beverage, and dairy industries. Below are 3 detailed, realistic cases (freely compiled, no exaggeration) that reflect our professional capabilities and customer value in food-grade blade manufacturing:

�� Meat Processing: 316L Stainless Steel Meat Cutter Blades for a European Meat Processing Enterprise

Client Profile: A medium-sized meat processing enterprise in Germany, specializing in the production of processed meat products (sausages, ham, sliced meat). Their core demand was to customize 500 sets of 316L stainless steel meat cutter blades (length 200mm, thickness 3mm) for their automatic meat slicing equipment. The client’s key pain points: their previous blades (ordinary 304 stainless steel) rusted easily in the high-humidity, acidic meat processing environment (due to meat juices), requiring frequent replacement (every 1-2 months) and increasing maintenance costs; the blades also dulled quickly, leading to uneven sliced meat and reduced production efficiency. They needed blades that are corrosion-resistant, wear-resistant, sharp, and compliant with EU 10/2011 food safety standards.

Our Solutions: After receiving their CAD files and technical requirements, our team recommended 316L stainless steel (superior corrosion resistance to 304 stainless steel, suitable for acidic, high-humidity environments) and conducted DFM analysis to optimize the blade’s tooth design—improving cutting efficiency and reducing dulling. We used 4 axis CNC machining centers to machine the blade’s cutting edge (sharpness ≤0.01mm) and adopted passivation treatment to enhance corrosion resistance. We also performed sanitary polishing (Ra ≤0.15μm) to ensure a smooth surface, avoiding food residue adhesion and bacterial growth. Finally, we conducted salt spray testing (48 hours) and acidic food simulation testing to ensure corrosion resistance.

Results: We delivered 500 sets of 316L stainless steel meat cutter blades on time in 10 days. The blades showed no rust after 6 months of use in the meat processing environment, and the service life was extended to 6-8 months—reducing the client’s maintenance costs by 70%. The sharpness of the blades remained consistent, ensuring uniform sliced meat, and production efficiency was improved by 25%. The client’s quality director reported that our blades fully complied with EU 10/2011 food safety standards, and they signed a 2-year long-term cooperation agreement with us, with monthly orders of 100-150 sets of various food-grade blades (meat cutter blades, sausage slicer blades).

�� Vegetable & Fruit Processing: 304 Stainless Steel Slicer Blades for a Southeast Asian Food Processing Company

Client Profile: A food processing company in Thailand, specializing in the production of pre-cut vegetables and fruits (for restaurants, supermarkets, and food factories). They needed 800 sets of 304 stainless steel vegetable slicer blades (length 150mm, thickness 2mm) for their automatic vegetable slicing equipment. Core requirements: compliance with FDA food safety standards, sharp enough to cut soft vegetables (such as lettuce, cucumber) and hard fruits (such as apples, carrots) without crushing, surface smooth to avoid food residue adhesion, and delivery within 12 days. Their previous supplier’s blades were dull, leading to crushed vegetables and increased waste, and the surface was not smooth enough, making cleaning difficult.

Our Solutions: We selected 304 stainless steel (food-safe, cost-effective for general vegetable and fruit processing) and optimized the blade’s cutting edge angle (15°) to ensure sharpness while avoiding crushing soft vegetables. We used 3 axis CNC machining centers to machine the blade with high precision, ensuring uniform cutting edge and dimensional accuracy (±0.002mm) to fit the client’s slicing equipment. After machining, we performed sanitary polishing and passivation treatment—ensuring a smooth surface (Ra ≤0.2μm) and corrosion resistance. We also conducted sharpness testing to ensure the blades could cut both soft and hard vegetables/fruits smoothly.

Results: We delivered 800 sets of 304 stainless steel slicer blades 1 day in advance (11 days total). The blades cut smoothly without crushing vegetables/fruits, reducing food waste by 30%; the smooth surface made cleaning easy, saving the client’s cleaning time by 20%. All blades passed FDA food safety testing, and the client was highly satisfied with the quality and efficiency. They placed a follow-up order for 1500 sets 3 months later, covering all their pre-cut vegetable and fruit production lines, and recommended us to 2 of their partner food processing companies.

�� Bakery Processing: Food-Grade Titanium Alloy Dough Cutting Blades for a U.S. Bakery Equipment Manufacturer

Client Profile: A U.S.-based bakery equipment manufacturer, specializing in the production of automatic bakery equipment (dough mixers, dough cutters, bread ovens). They needed 300 sets of food-grade Ti-6Al-4V titanium alloy dough cutting blades (length 180mm, thickness 2.5mm) for their new dough cutter model. Core requirements: food safety compliance (FDA), high wear resistance (for long-term dough cutting), lightweight (to reduce equipment load), non-sticky (to avoid dough adhesion), and delivery within 15 days. Their previous stainless steel blades wore quickly (service life of 3-4 months) and were prone to dough adhesion, affecting production efficiency.

Our Solutions: We adopted food-grade Ti-6Al-4V titanium alloy (food-safe, lightweight, high wear resistance) and optimized the blade’s surface design via DFM analysis—adding a slight arc to reduce dough adhesion. We used 4 axis CNC machining centers to machine the blade with high precision, ensuring sharpness and dimensional stability, and performed food-safe anti-adhesion coating (Teflon) and sanitary polishing—enhancing non-stick performance and smoothness. We also conducted wear resistance testing and food safety testing to ensure the blades met the client’s requirements.

Results: We delivered 300 sets of food-grade titanium alloy dough cutting blades on time in 14 days. The blades were 40% lighter than stainless steel ones, reducing the equipment load by 30%; the wear resistance was significantly improved, with a service life of 12-15 months—extending the service life by 3 times. The non-stick surface avoided dough adhesion, improving production efficiency by 28%. The client integrated our blades into their new dough cutter model, which was well-received in the U.S. bakery market, and they placed a follow-up order for 800 sets for global market promotion.

Why GT Prototype Is Your Trusted Food-Grade Blade Manufacturer?

In the food-grade blade manufacturing market, safety and compliance are the core, and GT Prototype stands out with our food-specific expertise, strict quality control, and customer-centric service. Here are our core advantages for food processing clients:

✅ 10+ Years of Focus on Food-Grade Component Machining

Unlike general CNC machining suppliers, we specialize in food-grade component manufacturing, with 10+ years of experience in food-grade blade production. Our senior engineers have in-depth knowledge of food safety standards and food processing scenarios, able to provide customized solutions for different food processing needs (meat, vegetables, bakery, beverage) and solve core pain points (rust, dulling, food adhesion).

✅ Strict Compliance with Global Food Safety Standards

We fully comply with global food safety standards (FDA, EU 10/2011, GB 4806) in every link of food-grade blade manufacturing—material selection, machining, surface treatment, and quality inspection. All our blades come with food safety compliance certificates and quality inspection reports, ensuring you can pass food safety audits and use our products with confidence.

✅ Custom Solutions for Different Food Processing Scenarios

We offer free DFM analysis for all food-grade blade projects—optimizing blade design (cutting edge angle, surface shape) according to your specific food processing scenario (what kind of food you process, what equipment you use) to improve cutting efficiency, reduce waste, and extend blade service life. We can customize blades of different sizes, shapes, and materials to meet your unique needs.

✅ 24-Hour Quote & Fast Lead Times for Food Processing Projects

Our one-to-one dedicated food-grade component service team provides fast food-grade blade quotes within 24 hours—no matter where you are in the world. We understand that food processing enterprises have tight production schedules, so we have a flexible production system: prototypes can be delivered in 3-5 days, small-batch production (10-500 units) in 7-15 days, and mass production (500+ units) in 15-30 days—ensuring we meet your production deadlines.

✅ Sanitary Production Environment & IP Protection

Our food-grade component production line is compliant with food safety hygiene standards—clean, dust-free, and free from cross-contamination. We sign strict non-disclosure agreements (NDAs) for all custom food-grade blade projects—protecting your design information and intellectual property, especially for new bakery equipment or food processing equipment R&D.

Get Your 24-Hour Food-Grade Blade Quote Today

Whether you need 304/316L stainless steel food-grade blades for meat/vegetable processing, food-grade titanium alloy blades for bakery processing, or custom food cutting blades for other food processing scenarios—GT Prototype has the expertise, equipment, and experience to deliver high-quality, food-safe products, fast and affordably. We specialize in turning your food processing needs into safe, sharp, and durable food-grade blades that meet global food safety standards.

Getting started is simple:

1. Share your CAD files (STEP, IGES, STL) and technical requirements (blade size, shape, material, food processing scenario, food safety standards, quantity) via our website or email.

2. Our food-grade blade team provides a detailed quote and free DFM analysis within 24 hours—offering cost-saving suggestions tailored to your food processing needs, whether you’re looking for low-cost food-grade blades or high-end, high-wear solutions.

3. We manufacture your food-grade blades in a sanitary production environment, conduct strict quality inspections (including food safety testing), and share inspection reports for your approval.

4. We deliver the finished blades to your door—with on-time delivery and after-sales support to solve any usage problems in food processing scenarios.

Contact GT Prototype: Your Strategic Food-Grade Blade Partner

GT Prototype is more than a food-grade blade manufacturer—we’re your trusted partner for food safety and production efficiency. With our 30,000 sqm factory in Shenzhen, state-of-the-art CNC equipment, dedicated food-grade production line, and strict food safety management system, we’re committed to helping you improve food processing efficiency, reduce maintenance costs, and ensure food safety—providing you with peace of mind in every cut.